China Texitle inkjet ink production

Introduction

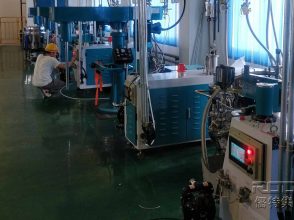

- Application equipment: 6 sets of RTSM-10BJD ceramic nano pin type horizontal bead mill

- Grinding process: Each bead mill in recycling grinding

- Material: Textile disperse dye type inkjet ink

- Feeding size: D90<10μm

- Finish size: D90<200nm

This project is invested by Root old customer from Taiwan. In 2015, Root has sold several sets of bead mill to DBC, one of the biggest inkjet ink manufacturer in Taiwan for the production of disperse dye type inkjet ink. Root bead mill performance can compete with DBC’s Nestzch bead mill and the bead mill has worked stability and the product quality fulfills customer requirement. After DBC invest their new factory in Jiangsu province, they have still selected to cooperate with Root and purchased 6 sets of RTSM-6BJD for their new factory.

Main Equipment

RTSM-BJD series horizontal bead mill has adopted ceramic rotor and chamber. This series of product has covered laboratory and industrial models. RTSM-BJD series ceramic bead mill has been widely applied in nano grade grinding and metal pollution sensitive industry with its high efficiency and non-pollution property.

According to hydrodynamics, different grinding rotor structure will have different function on the grinding media movements trace, therefore has different effect on the material flow and grinding media flow. Due to the different properties of different material, high viscous or low viscous, high solid content or low solid content, high density or low density, high hardness or low hardness, the material will form different material flow and it needs different kinds of grinding strength, method, grinding media movements to grind, shear and disagglomerate. So for same series of RTSM-BJD, there are many different kinds of rotor structure to suit with different material.